IS-B Low-Reflection Black Process

New common sense!! Low reflection process that is neither thin film nor coating.

A solution to the problem of foreign objects by falling out and change over time, which has been a problem in the past!

Black matte stainless steel with no paint.

A new material that could not be achieved by painting on metal!

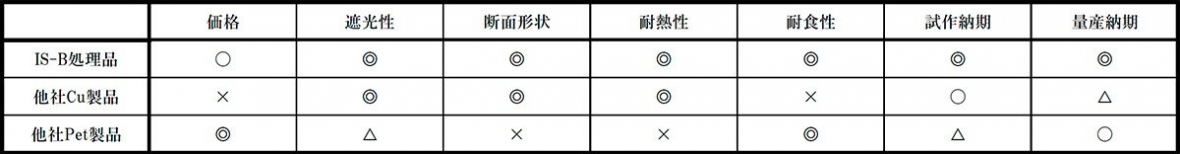

Superiority in thickness accuracy

No change in material thickness due to the matting process.

Achieves high-precision thickness variations such as 0.03mm/0.04mm/0.05mm/0.06mm, etc.

Material: Stainless steel

Realizes strength, durability, and heat resistance that cannot be achieved with resin products.

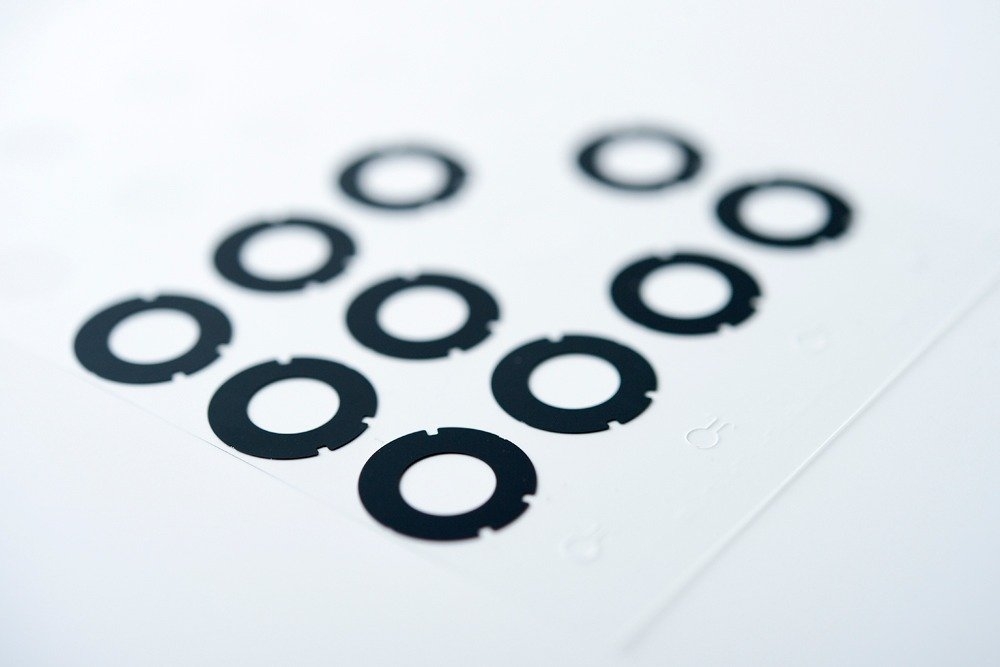

Perfect match with etching process.

No dimensional change in the surface process, so it does not damage the high precision of the etching process. " What we consider is not only what we can see."

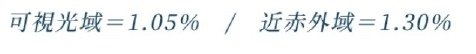

With the effect of a special surface condition that has never been seen before, light reflection can be controlled to about 1%.

Also, its low reflectance is maintained even in the near-infrared region where the reflectance normally increases in the matting process.

Cut ghosting and flare!

There are various advantages by adopting metal as a material for optical components.

On the other hand, it is also a material that is very difficult to reduce surface reflectance.

Even if the reflectivity is controlled by matte coating, there is still the issue of dimensional accuracy caused by variations in film thickness.

In order to meet the demand for dimensional accuracy in modern lens units, it has chosen the method to make the metal itself color black.

Optical properties are enhanced by a combination of a matting process and an oxidation coloring method, which are new technologies.