Silverson Mixers

Silverson Mixers

Silverson has been supplying high-quality mixers to industries around the world for over 60 years.

Customers include leading companies in the food, pharmaceutical, cosmetic and chemical industries in over 150 countries.

The Silverson mixer is a high shear mixer that can realize unparalleled efficiency in a variety of applications.

Silverson Mixer Features

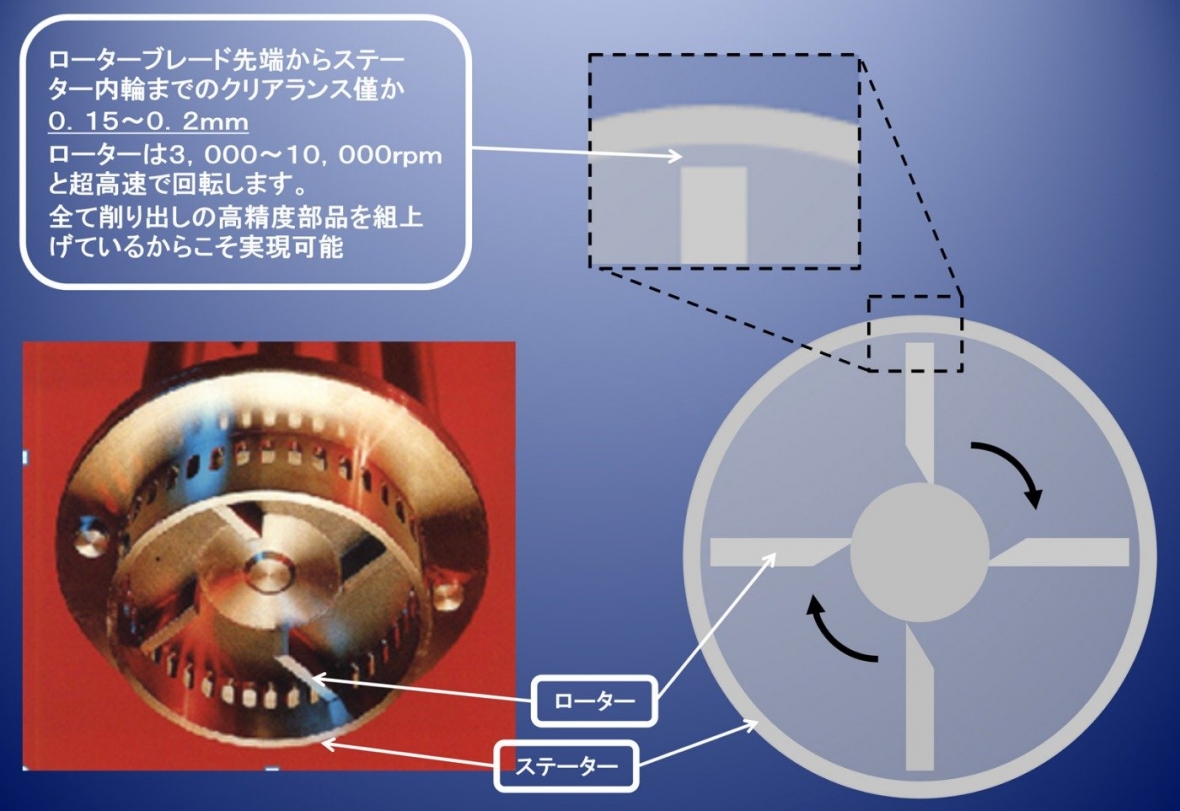

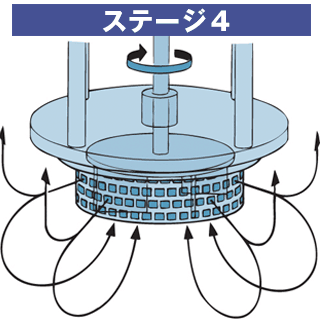

- Rotor / stator type work head structure that demonstrates high shearing force.。

- Ultra-high speed rotation can be realized only by the high-quality mixer using high-precision parts.

- A work head structure that can be easily replaced and diversity that can be realized by various work heads that can be selected according to the application.

- Sanitary property that is obtained by a well-considered design for cleaning and wetted parts structure.

- As a lineup of small, medium, and large mixers with a unified basic structure, it is possible to easily scale up evaluation results on a pilot scale.

Various mixer comparisons

Rotor/Stator Relationship diagram

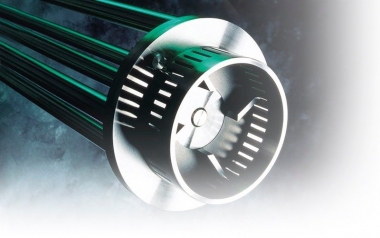

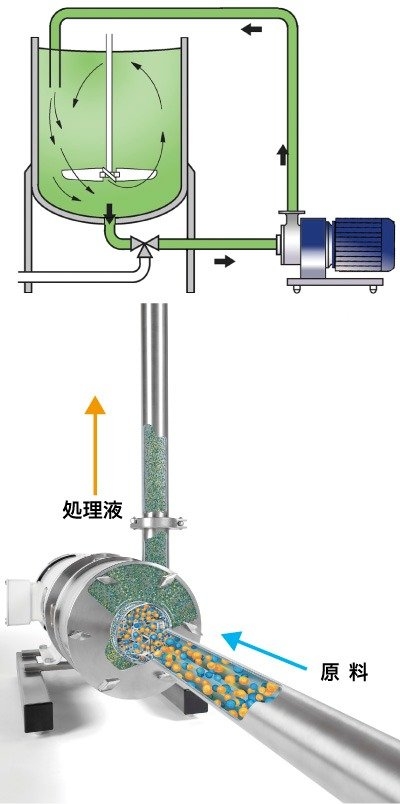

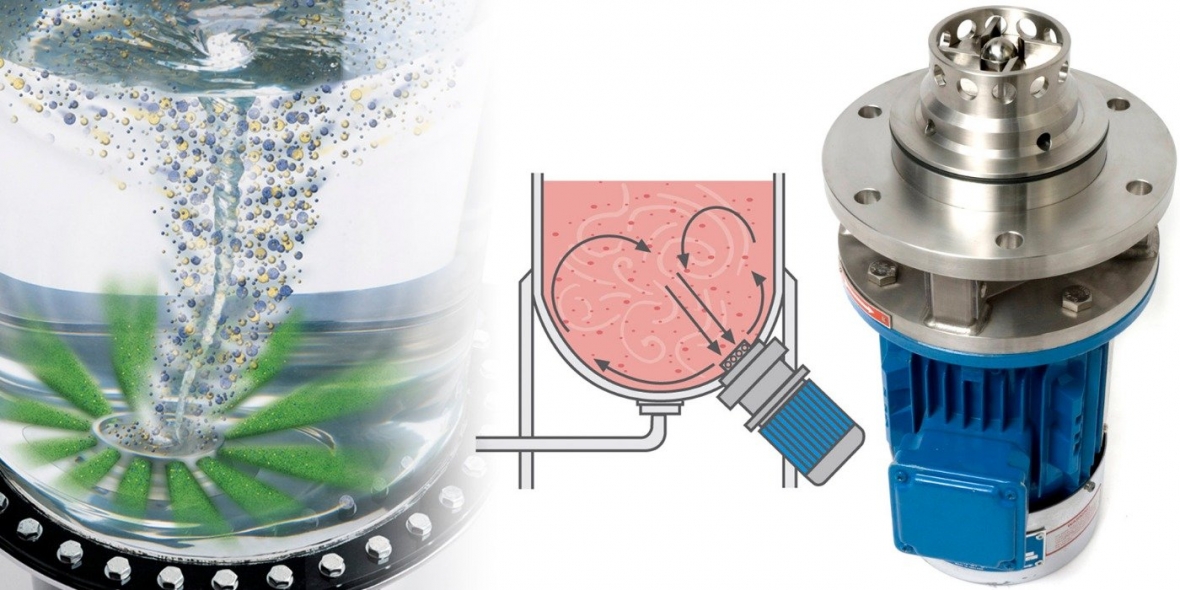

Silverson Mixer Operating principle

As the rotor rotates at high speed inside the workhead, a strong suction force is generated, and liquids and solids are sucked in from the underside.

Liquids and solids sucked into the workhead are pushed outward due to the centrifugal force created by the rotation of the rotor, and are strongly sheared as they pass through the small clearance between the rotor and stator.

The powerfully sheared solution is discharged through the stator opening.

At this time, strong liquid shearing occurs.

The solution discharged from the workhead flows along the inner wall of the tank, and at the same time new material is sucked in from the underside of the head so that continuous shearing and stirring action continues.

Interchangeable workheads

All Silverson Mixers are equipped with workheads that can be easily replaced according to the application.

By selecting a workhead according to the purpose of mixing, emulsifying, homogenizing, disintegrating, dispersing, subdividing, and de-agglomerating, it is possible to perform various operations with one mixer.

- General round hole stator: Applicable to a wide range of applications. Agglomerate disintegration, gelling agent and thickener dispersion, emulsion and slurry dispersion, etc.

- Emulsor Screens: liquid + liquid mixing, emulsification, etc.

- Slotted Disintegrating Head: the disintegration of fibrous materials such as animal and vegetable tissue, the disintegration and solubilization of elastic materials such as rubbers and polymers.

- Square Hole High Shear Screen: The highest shearing force. Disintegration and emulsification into crystalline solids.

Laboratory Mixer

A single Silverson laboratory mixer can fit a variety of applications.

You can select and use the most suitable workhead from a variety of more than 40 types according to your purpose, such as mixing, emulsifying, homogenizing, disintegrating, dispersing, subdividing, and de-agglomerating. You can get the correct information you need when scaling up to a production line.

Model L5MA

- Device dimensions: W300 x D500 x H940

- Processing liquid volume: MAX 12L (about water)

- Processing liquid volume: MAX 12L (about water)

Desktop type inline type

- Device dimensions: W200 x D600 x H346

- Processing liquid volume: MAX 25L / min (about water)

- Motor: 746KW, rotation speed ~ 10,000rpm

Batch Mixer

Silverson Batch Mixer can be inserted from the top of the tank.

It is a highly versatile model according to various applications.

We have a lineup of small, medium, and large sizes, and can handle a range of 5 to 30,000 liters.

Model AX-3

- Frame dimensions: 450mm

- Processing liquid volume: MAX 70L (about water)

- Motor: 250-500W, rotation speed 3,000rpm

Model GX20

- Frame dimensions: 1,220mm

- Processing liquid volume: MAX 2,250L (about water)

- Motor: 15KW, rotation speed 3,000rpm

Model MX

- Processing liquid volume: MAX 2,000L

- Motor: 55KW, rotation speed 1,000rpm

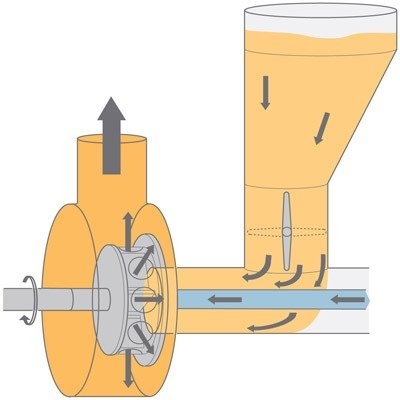

Duplex Mixer

In a duplex mixer, the upper and lower workhead are installed back-to-back, and the upper head sucks materials that tends to float downward, while the lower head sucks materials that tends to sink upward.

It activates liquid circulation in the tank, and demonstrates a high shearing effect due to the double workhead.

Ultramix

Ultramix is a new product developed for the purpose of powerfully stirring the solution with stirring that does not require high shearing force like the rotor / stator type High Shear Mixer.

It is possible to install it in a small space due to its small, high-speed rotating head.

It is effective for stirring solutions in IBC containers with small apertures.

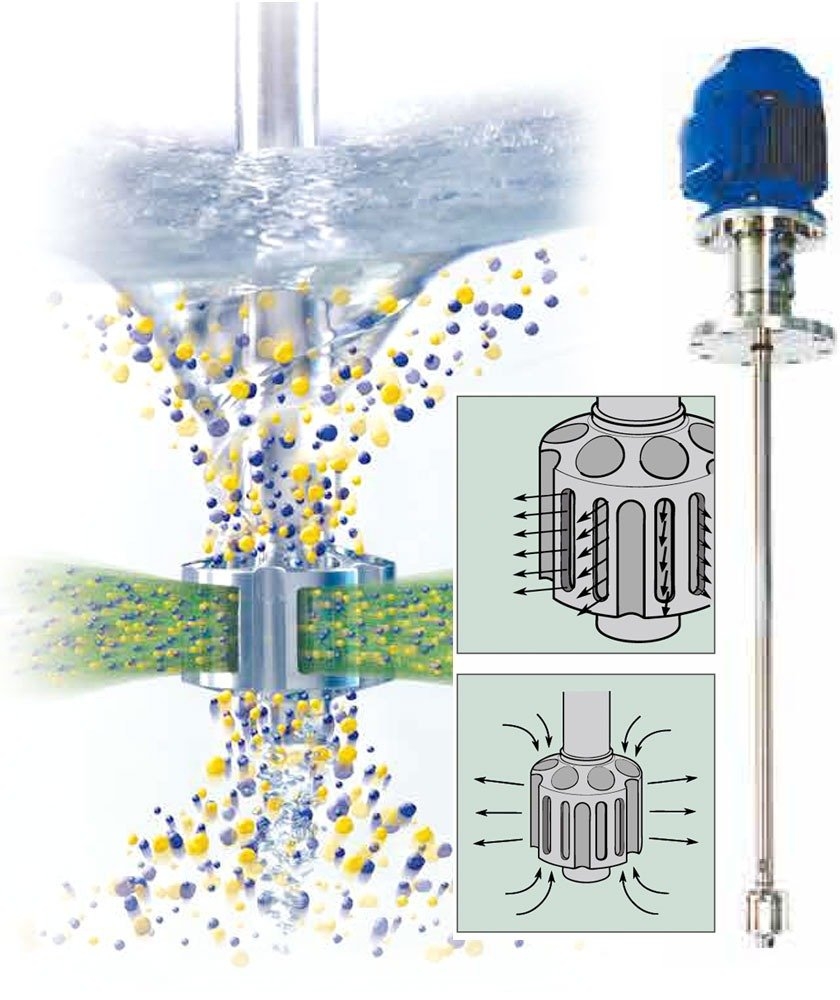

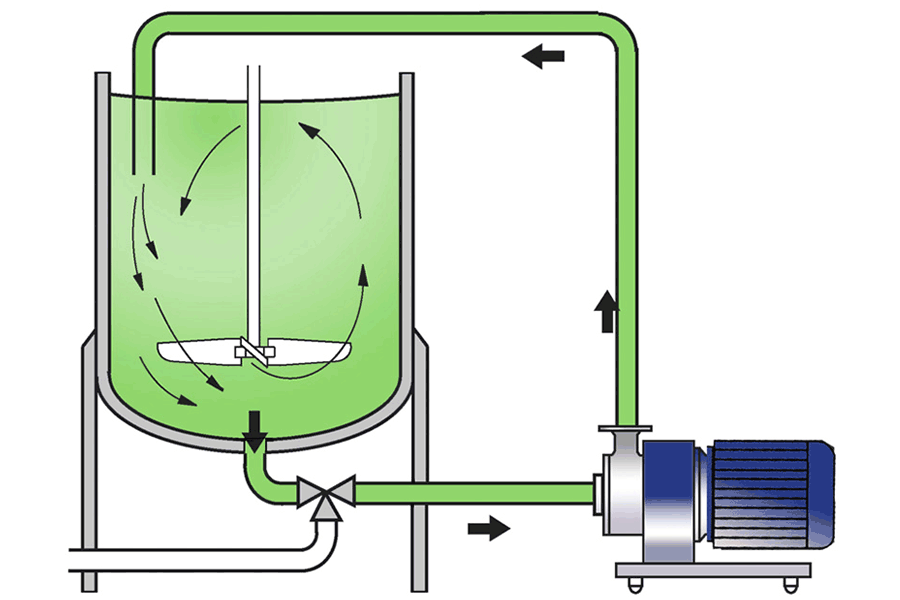

In-Line Mixer

Silverson In-Line Mixer keeps the high shear effect generated by the rotor and stator, and by passing the solution in the tank evenly through the workhead, it can exhibit mixing effect without air contamination.

It is easy to retrofit to the existing stirring line and has a pumping effect, so it can produce a large effect at low cost.

Workheads can also be easily replaced to support various applications.

Sanitary property and maintainability are excellent and can be used safely for a long time.

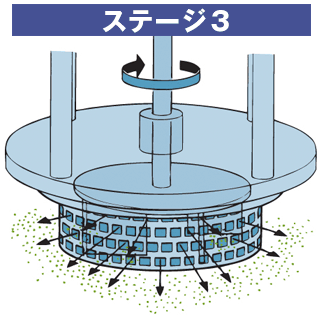

In-Line Mixer Operating principle

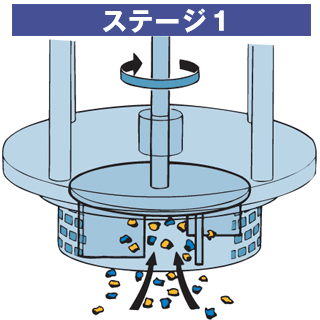

Stage 1

As the rotor rotates at high speed inside the workhead, a strong suction force is generated, and liquids and solids are sucked in from the workhead inlet.

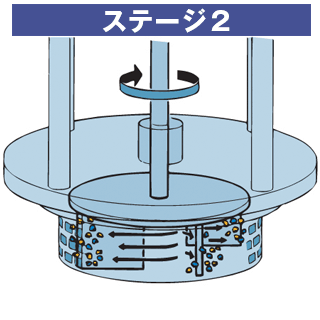

Stage 2

Liquids and solids sucked into the workhead are pushed outward due to the centrifugal force created by the rotation of the rotor, and are strongly sheared as they pass through the small clearance between the rotor and stator.

Stage 3

The powerfully sheared solution is discharged through the stator opening.

At this time, strong liquid shearing occurs.

The solution is pushed out from the outlet, and at the same time new material is sucked in from the inlet of the head so that continuous shearing and pumping action continues.

In-Line Mixer Installation case

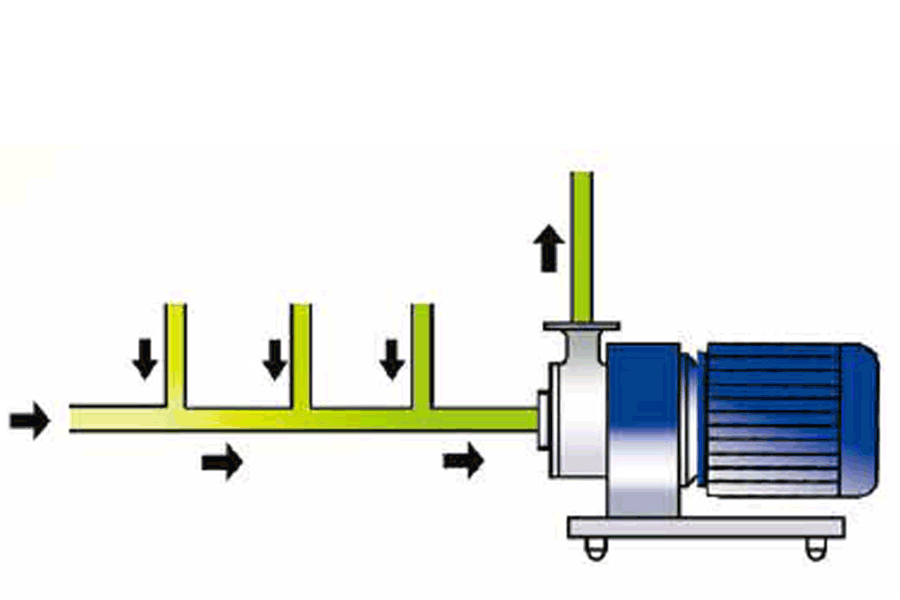

Flashmix

The Flashmix was developed by Silverson with all of its expertise in powder/liquid mixing processes. It enables high-speed powder suction and realizes high-speed mixing processing.

The solution mixed by the high-precision In-Line Mixer is in a homogeneous state without powder lumps or air mixing.

Tri-clamp fittings are standard standard specification, making it easy to add to existing systems. It has excellent sanitary properties and can be used for Cleaning-In-Place (CIP).

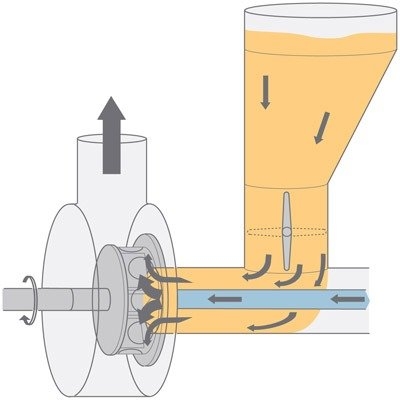

Flashmix Operating principle

Stage 1

As the rotor rotates at high speed inside the workhead, a strong suction force is generated, and liquids are sucked in from the workhead inlet.

Stage 2

By opening the butterfly valve of the hopper containing the powder, the powder is drawn into the liquid stream and sucked into the workhead.

Stage 3

The powerfully sheared solution is discharged through the stator opening.

At this time, strong liquid shearing occurs.

The solution is pushed out from the outlet, and at the same time new material is sucked in from the inlet of the head so that continuous shearing and pumping action continues.

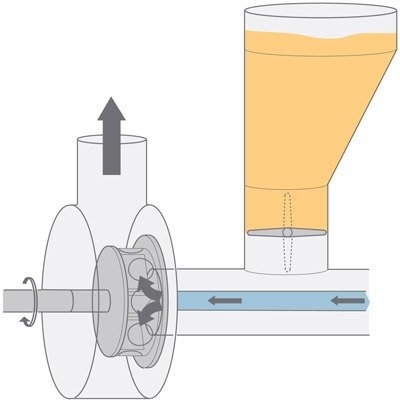

Bottom Entry Mixer

The Bottom Entry Mixer is a rotor/stator type mixer installed at the bottom of the tank. Since the motor and the workhead are directly connected, it has high rigidity, and is suitable for use in the high viscosity solution manufacturing process by crushing large masses and combining with a low-speed agitator or a scraper type agitator.

Silverson mixers are used in a wide range of industries around the world.

Food Field

- Flavoring emulsions

- Beer brewing process

- Jam pectin

- Salad dressing

- Soft drinks, artificial sweeteners, syrups

- Tomato sauce, ketchup, mustard

- Margarine, low-fat spreads

- Ice cream, yogurt

- Pet food, etc.

Pharmaceuticals and Cosmetics Field

- Cosmetic creams and lotions

- Deodorants, antiperspirant

- Surfactant production and dilution

- Sunburn creams

- Shampoos

- Carbomer dispersion and dissolution

- Nail polish

- Syrups, water pills

- Creams and ointments

- Sterile mixing in clean room

Chemical & Petrochemical Field

- Modified Asphalt Polymer Mixing

- Filter cakes

- Titanium dioxide production, dispersion

- Lubricating oil Polymer dissolving

- Bentonite

- Paper coating liquid

- Drilling mud

- Rubber disintegrating and dissolving

- Pesticides, insecticides

- Car wax

- Inks, paints

Electronic Device Field

- Silica Dispersion

- Slurry

- Electronic materials, pre-treatment for wet dispersing

Custom Support

In order to meet specific process requirements for customers, Silverson proactively offer customized support.

■Wetted part material

Standard: SUS316L

Option: Titanium, Hastelloy, Special stainless steel, etc.

■Motor

Standard: Fully closed fan cooling motors

Option: Explosion-proof motor, stainless steel motor, waterproof motor, etc.

■Seal

Sanitary specifications

Standard: Single mechanical seal

Option: Double mechanical seal

■Special cases

Systematization: System provision including tanks, piping, control panels, etc.

In-Line Mixer: jacket housing, etc.

Test support and after-sales service

■Test support

In order to satisfy the customers'requests for testing, Silverson cooperate with Japanese office after detailed meetings, and conduct manufacturer's testing by receiving samples or lending test equipment for testing at the customer's site.

■after-sales service

In cooperation with Japanese office, Silverson have established a service system that includes the provision of standard parts and prompt response in case of machine trouble.

Silverson handles a wide range of agitators to solve the problems faced by customers in various fields.

In addition, not only as a simple trading company function, but also as a technical consultant for all agitation processes, Silverson can provide the most suitable proposals to customers using the expertise we have accumulated.